High wear-resistant PVC car interior leather is a high-performance fabric designed for car interiors, suitable for a variety of interior decoration materials such as car seats, door interiors, armrest...

See Details

Inquiry Now

The Synthetic Evolution: Defining Faux and PVC Leather When exploring the pros and cons of faux leather versus PVC leather, we must first clarify that this is not just a competition between two materials, but a strategic choice in modern chemical engineering within the footwear industry. Faux Leather is a broad term en...

View MoreAnatomy of Modern Synthetic Footwear In today's footwear manufacturing industry, Polyvinyl Chloride (PVC) has evolved far beyond a simple plastic substitute into a highly engineered material. To understand its disadvantages, we must first analyze the physical structure of PVC Synthetic Leather for Shoe Uppers. This mat...

View MoreWhat is PVC Synthetic Leather? PVC Synthetic Leather for Sofa (Polyvinyl Chloride synthetic leather) is one of the most widely used man-made materials in the furniture industry. It is not a simple sheet of plastic but a complex composite structure created by combining PVC resin with various additives to simulate the te...

View MoreSynthetic leather, often referred to as artificial or ecological leather, has become increasingly popular in the furniture industry due to its adaptability, variety of textures, and cost-effectiveness compared to natural leather. Dongtai Fuan Synthetic Materials Co., Ltd., established in 2007, specializes in producing high-quality ecological synthetic leather with an annual production capacity of 20 million square meters. Their products cover diverse applications, including car upholstery, garment leather, decorative leather, shoe leather, luggage, and more than 100 varieties for different uses. Specifically for sofa applications, the wear resistance and tear resistance of synthetic leather are critical parameters, determining the durability and longevity of furniture products under regular use.

The wear and tear performance of synthetic leather is influenced significantly by its composition and structural design. Typically, synthetic leather is made by coating a base fabric, often polyester or cotton, with a polyurethane (PU) or polyvinyl chloride (PVC) layer. The coating provides surface properties, including texture, color, and mechanical resistance. Ecological synthetic leather, such as that produced by Dongtai Fuan Synthetic Materials Co., Ltd., incorporates advanced materials and production technologies to enhance durability. The combination of a flexible backing fabric and a robust polymer layer helps distribute stress during use, improving both wear resistance and tear resistance for sofas.

Wear resistance refers to the ability of synthetic leather to withstand surface abrasion caused by friction, contact with other surfaces, or repeated use. This property is particularly important for sofas, as cushions, seating areas, and armrests are subjected to daily mechanical stress. Synthetic leather achieves wear resistance through polymer composition, coating thickness, and surface treatment. Advanced ecological synthetic leathers are engineered to resist micro-scratches and surface dulling, maintaining appearance over extended periods. The presence of protective topcoats and anti-abrasion layers enhances the longevity of the sofa upholstery.

Tear resistance measures the capacity of synthetic leather to resist propagation of cuts or punctures. Sofas may encounter sharp objects, pet claws, or accidental impacts, making tear resistance a critical factor for long-term usability. Synthetic leather combines a flexible backing fabric with a polymer coating to distribute localized stress and reduce the likelihood of tearing. The reinforced fiber network in ecological synthetic leather improves its tensile strength and prevents small scratches from developing into larger tears. Dongtai Fuan Synthetic Materials Co., Ltd. emphasizes consistent fiber distribution and controlled coating processes to optimize tear resistance in their synthetic leather products for furniture applications.

Assessing wear and tear resistance of synthetic leather requires standardized testing methods. Common tests include Martindale abrasion testing, Taber abrasion testing, and tensile tear testing. Martindale testing evaluates how many rubbing cycles a sample can withstand before visible wear occurs, simulating everyday use of sofa surfaces. Taber abrasion measures weight loss or surface changes after rotational rubbing under specified loads. Tensile tear tests measure the force required to propagate an initial cut, indicating the material’s resistance to accidental punctures. Synthetic leathers from Dongtai Fuan undergo rigorous quality control and testing to ensure their durability and performance meet industry standards.

The table below summarizes typical performance metrics for synthetic leather used in sofas, comparing ecological synthetic leather with standard synthetic leather and natural leather.

| Material Type | Wear Resistance (Cycles to Abrasion) | Tear Resistance (N/mm) | Recommended Sofa Application |

|---|---|---|---|

| Ecological Synthetic Leather (Dongtai Fuan) | 50,000–70,000 | 15–22 | High-traffic areas, family sofas, commercial furniture |

| Standard Synthetic Leather | 30,000–50,000 | 10–15 | Moderate-use sofas, decorative furniture |

| Natural Leather | 40,000–60,000 | 12–18 | Premium sofas, low to medium-traffic areas |

Surface treatments, such as polyurethane finishing, anti-scratch coatings, and UV protection layers, significantly affect wear and tear resistance. For sofas, these treatments prevent fading, micro-abrasion, and surface cracking over time. Dongtai Fuan Synthetic Materials Co., Ltd. integrates specialized coatings that enhance surface durability while maintaining texture and softness. These treatments contribute to consistent performance in daily use scenarios, including sliding, sitting, and light friction from clothing or accessories. Proper surface engineering ensures the synthetic leather remains functional and visually appealing for years.

Wear and tear performance is also influenced by environmental conditions and usage patterns. Factors such as humidity, temperature fluctuations, direct sunlight exposure, and regular cleaning routines affect durability. In high-humidity environments, synthetic leather may absorb moisture, potentially softening the polymer layer and reducing wear resistance. Continuous exposure to UV light can degrade surface coatings. Proper maintenance practices, including gentle cleaning, avoiding sharp objects, and limiting direct sunlight exposure, enhance the service life of sofa synthetic leather. Dongtai Fuan emphasizes production methods that enhance environmental stability to maintain performance under varied conditions.

Regular care and maintenance are essential to sustain wear and tear resistance. Recommendations include using mild cleaning agents, wiping spills promptly, and avoiding abrasive materials during cleaning. Rotating cushions and avoiding concentrated pressure points helps distribute stress evenly. Applying protective conditioners and maintaining proper indoor humidity can prevent surface degradation and retain softness. Following these maintenance practices ensures that ecological synthetic leather maintains its mechanical properties and aesthetic appeal, making it suitable for family use and high-traffic areas.

The table below illustrates how maintenance practices influence the expected service life of synthetic leather for sofas.

| Maintenance Level | Wear Resistance (Cycles) | Tear Resistance (N/mm) | Expected Lifespan |

|---|---|---|---|

| High Maintenance | 60,000–70,000 | 20–22 | 8–10 years |

| Moderate Maintenance | 50,000–60,000 | 15–20 | 5–8 years |

| Low Maintenance | 30,000–50,000 | 12–18 | 3–5 years |

Ecological synthetic leather from Dongtai Fuan is particularly suitable for sofas in residential and commercial settings. In family living rooms, high-traffic areas require materials with high wear resistance to withstand daily use. Commercial furniture, such as waiting rooms or hotel lounges, also benefits from synthetic leather with reinforced tear resistance. Additionally, ecological synthetic leather offers consistent texture, color, and surface feel, ensuring that sofas maintain their appearance and comfort over time. Its versatility allows it to be applied to a wide range of furniture designs while supporting long-term durability.

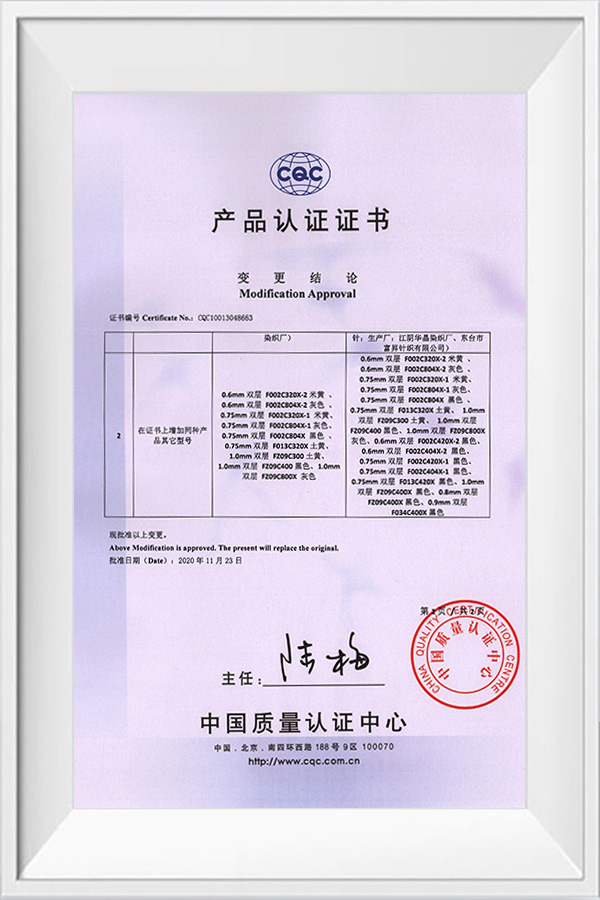

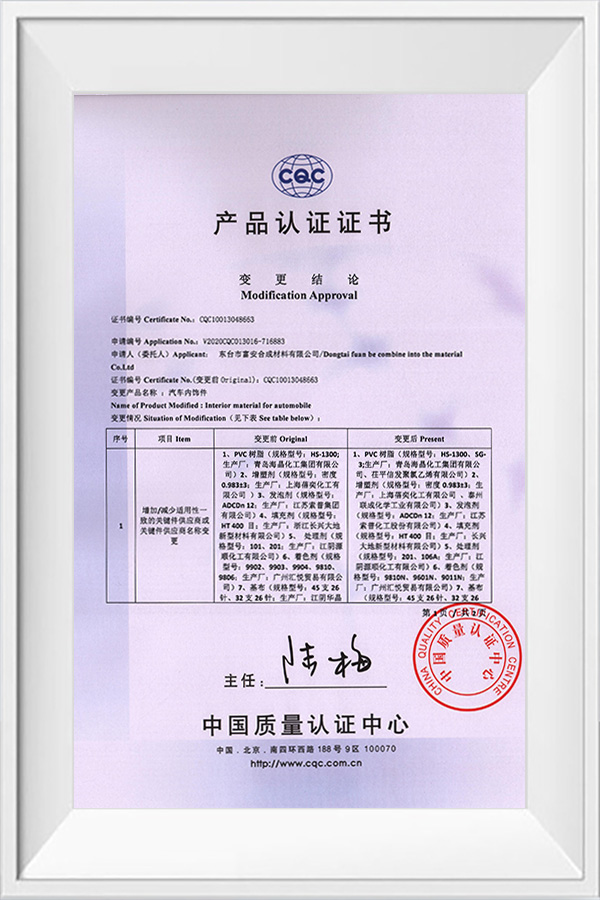

Dongtai Fuan Synthetic Materials Co., Ltd. has passed 3C, ISO/TS16949, and intellectual property management system certifications, reflecting rigorous quality control and manufacturing standards. These certifications ensure that synthetic leather meets durability and safety requirements for furniture applications. Quality assurance processes include regular testing for abrasion, tear strength, and coating integrity, supporting reliable performance in sofa upholstery. Additionally, the company’s modern management systems and safety measures contribute to consistent production quality, reinforcing the reliability of ecological synthetic leather products.

Synthetic leather for sofas, particularly ecological varieties produced by Dongtai Fuan Synthetic Materials Co., Ltd., demonstrates reliable wear resistance and tear resistance when designed, manufactured, and maintained properly. Factors such as material composition, polymer coating, surface treatments, environmental exposure, and maintenance practices collectively influence the durability of synthetic leather. Standardized testing methods, including abrasion and tear tests, provide measurable indicators of performance, ensuring that sofas maintain functionality and appearance over time. With proper care and application, synthetic leather offers a durable, versatile, and aesthetically consistent solution for residential and commercial sofa upholstery.